Woodworking with Maple

Along with cherry, walnut and oak, maple is considered to be among the favorite hardwood choices for furniture building. Maple is generally considered to be strong, durable and very pretty when properly finished.

Maple does have it’s drawbacks. It can be temperamental, particularly when finishing, and is susceptible to shrinkage. Making sure that your maple is well-seasoned and properly acclimatized to your environment will make a big difference in how your maple woodworking projects turn out, and how they hold up over time.

Varieties of Maple:

When buying maple from your lumber supplier, you may hear plenty of names for the wood: tiger maple, curly maple, birds-eye maple, fiddleback maple, red maple, soft maple, hard maple – the list goes on.

First of all, soft maple and red maple are typically the same thing. And the term soft maple is a bit of a comparative misnomer, as soft maple is harder than many other hardwoods (such as cherry).

Soft maple is also often referred to as “tiger maple” for the tiger-like stripes in the wood, or curly maple, if the stripes are a bit more of the curly nature.

Hard maple varieties often will have more small knots that appear along the grain. This is often referred to as “birds-eye maple.”

For years, maple was the wood of choice for building musical instruments. The term “fiddleback maple” came from this industry, as properly matched boards would be used to make the large back panels of guitars and fiddles.

Woodworking with Maple:

Part of the beauty of a properly built piece of maple furniture comes from proper matching of corresponding boards. Care should be taken to ensure that grain colors and patterns between neighboring boards should match as closely as possible.

Many woodworkers will go as far as to buy thick maple stock and resaw it on a band saw, aligning the cut sides together for a perfectly matched pair of panels. This is particularly effective with tiger-striped maple used on drawer fronts and cabinet doors.

Because maple is such a hard wood, be certain that your tools, blades and bits are particularly clean and sharp.

Working with sharp tools on hard woods is not only going to product better results, but it is actually safer than if they are a bit dull, simply because the tools will cut cleaner (and be less prone to tearing through the wood).

Finishing Maple:

As with other hard woods such as cherry, maple can be a bit temperamental to finish, particularly when staining. When applying a stain, be sure to use a pre-stain conditioner to try and even out the “blotchy” patches that tend to appear. This won’t completely solve the problem though.

Stains tend to fill pores, cracks and crevices in wood. If the stain cannot find a pore to fill, it will be cleared away when the excess stain is wiped away.

The key to evening out the stain is to sand the project thoroughly, using progressively finer sandpaper grits. Start with 120 grit before moving up to 180, and finally 220. Try to evenly sand the entire project with this final sanding. Then, using some 320 grit paper, sand exposed end grain, which will tends to stain more heavily (sanding the end grain with finer grit will fill the pores of the end grain a bit more). Lightly wipe down the entire project before applying a pre-stain conditioner, followed shortly thereafter by the stain of your choice.

Another commonly used finishing technique on maple is to apply tung oil or linseed oil after the final sanding. These oils tend to bring out the curly or tiger looks of the maple. Follow the oil with a coat or two of shellac. For a more durable finish, top-coat over the shellac with a clear lacquer or polyurethane.

Get Instant Access To

16,000 Plans

Our special launch offer is ending soon!

Get instant access to all 16,000 plans to a large variety of projects… all for less than a night’s out.

All projects come with step-by-step details, plans, cutting & materials list and more

To top it off, you’ll get a 60 day, 100% risk-free money-back guarantee.

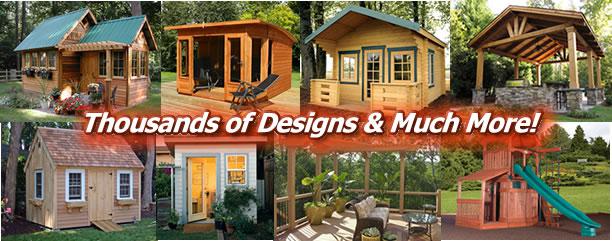

Check out these sheds you can build in a weekend or less:

Get thousands of plans!

Start Your Next Project With Teds’ Archive Of 16,000 Plans!

Instant access to all 16,000 woodworking plans with step-by-step details, photos, materials lists and more

Monthly free plans with lifetime membership access – No renewals, recurring fees or other charges